DS 6699

Silicone Sealant for Double-Glazed Glass

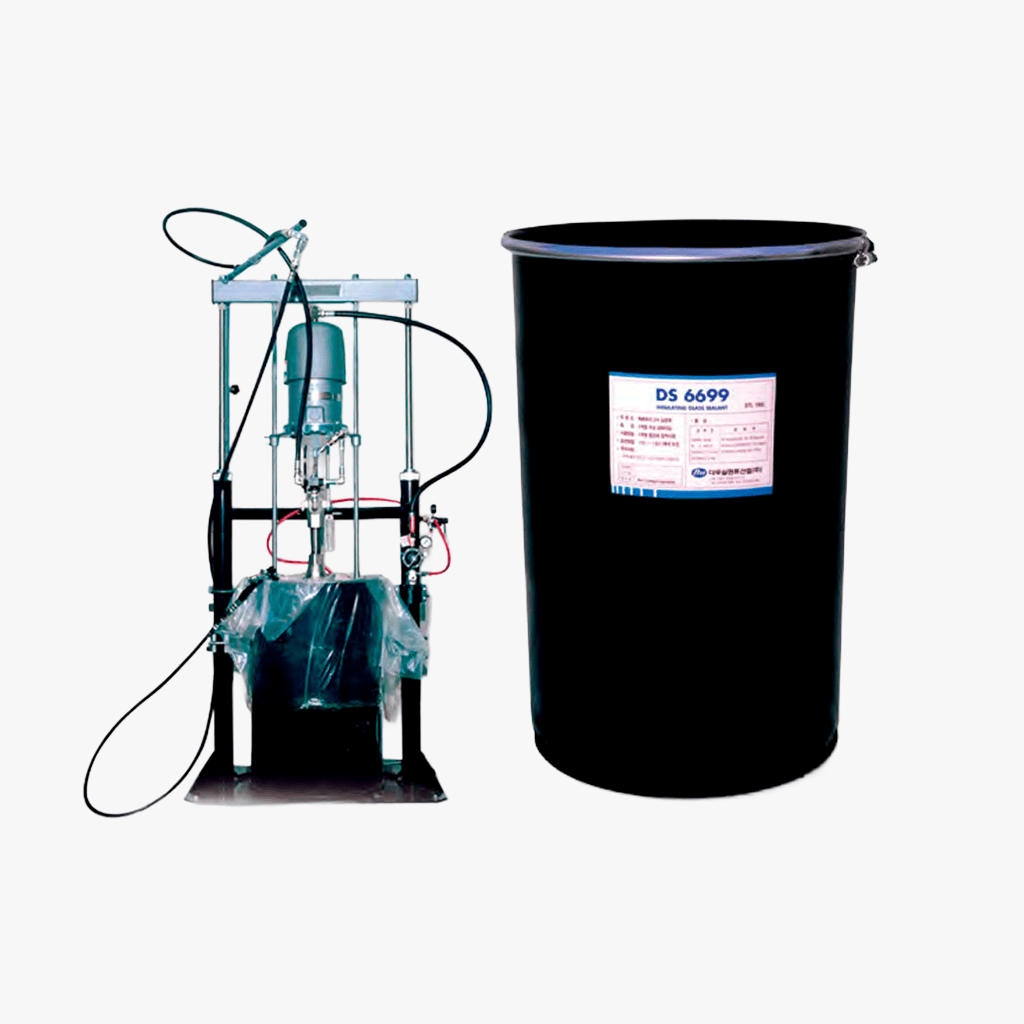

Easy to use and Economical Single-Component Sealant Supplied with a Drum Pump to Enhance Convenience in Double-Glazed Glass Production

- ColorBlack, White

- FEATURES

- Quick curing time

- Easy to use as a single-component product

- Excellent adhesion to glass and aluminum (spacers)

- Excellent weather resistance

- Excellent ozone and UV resistance

- Suitable for all seasons

- Applicable Temperature: -48~150°C

- Cost savings due to minimal sealant waste This eliminates sealant loss that can occur with the operation of pumps used for two-component poly-sulfide (Thiokol) or polyurethane sealants. Compared to sausage-type or cartridge-filled sealants, it significantly reduces the cost of purchasing sealant.

- Time and workforce savings Using the sealant dispenser attached to the pump for direct filling avoids the dual time waste of transferring sealant to a separate filling gun for caulking. The pump is easy to operate, requires no cleaning before or after use, and does not generate maintenance issues, thereby reducing the effort needed for securing skilled labor and managing equipment.

- APPLICATIONS

- For secondary sealing of residential double-glazed glass

- Not suitable for structural use.

PROPERTIES

Before Curing

- Curing TypeNeutral

- FormPaste

- Surface Curing Time20~30min. (23°C, 50%RH)

- Full Curing Time3~5days

- Working Temperature Range5~40°C (Substrate Temperature)

- Specific Gravity1.37

After Curing

- ASTM D2240 (Shore A)30~40

- ASTM D412 Maximum Tensile Strength1.0~1.5 N/mm2

- ASTM D412 Maximum Elongation400~600%

※ The data and figures provided are based on the Company’s standard testing specifications and are not intended as guarantees.

※ Adhesion strength may vary depending on the substrate material, so an adhesion test is required on the materials to be used before application.